A reliable, value-add soybean crush plant in Grand Forks, N.D.

Our Project

Epitome Energy is building a full-service soybean crush plant to address the region’s limited processing options, improve markets for area farmers, and support a reliable supply of soy products for fuel producers, food companies, and other agribusinesses.

Our value-adding facility will put more money into the pockets of hardworking farmers and provide a new, reliable source of high-quality soy products, such as:

Soybean Meal: More than 940,000 tons per year

Crude Degummed Soybean Oil: 60 million gallons per year

Soybean Hulls: 84,000 tons per year

Market Potential

Nearly one-third of the soybeans in the global market last year were produced by U.S. farmers. As a producer of several raw soy products, Epitome’s soybean processing plant will serve rising demand for renewable diesel fuel, biodiesel fuel, soybean oil, meal and livestock feed. The combined global market for these products is over $130 billion.

Soybean Oil

Soybean oil is the most-commonly used raw material in the production of renewable diesel fuels and is globally used as a food additive and cooking oil. Demand is projected to rise as many countries implement requirements to lower greenhouse gas emissions from transportation. There are currently at least six renewable diesel plants under construction across the United States.

Soybean Meal

Soybean meal is seeing growth as a high-protein additive and animal protein replacement in both human foodstuffs and animal feeds. A steady supply is essential to meeting the nutritional needs of livestock and consumers looking to shift away from animal-based protein products.

The meal market for livestock alone is over 375,000 tons within a 100-mile radius of the plant’s location, and includes turkey, hog, and dairy industries.

Soybean Hulls

Soy hulls are a growing source for supplemental feed for a variety of livestock. A natural by-product of the soybean crush process, soybean hulls are nutrient rich supplement to feeds for cattle, poultry, hogs, and even fish.

Strengthening the Regional Economy

For many farmers in the Red River Valley, the nearest facility capable of processing their crop is over 100 miles away. Without nearby processing, soybeans in the Red River Valley are regularly among the lowest-priced in the country, farmers pay higher transportation costs for their crop and are limited in the markets they are able to reach. Our planned crush plant in Grand Forks is projected to strengthen the basis for soybeans by 20-25 cents per bushel and process upwards of 42 million bushels per year.

Our plant will create 50-60 permanent jobs and indirectly support over 800 more in the Grand Forks area. Research from the University of Minnesota Extension Center has projected that a crush plant in the Red River Valley would create over $300 million in new economic activity.

Why Grand Forks?

Over the last two decades, soybean production has grown over 300% in the Red River Valley to become a growing agricultural staple. Building our facility in Grand Forks will support further growth and provide a crucial piece of the puzzle for farmers looking to reach new markets amidst the growing demand for soy products.

Grand Forks is also a community that cares for its people and businesses. The City of Grand Forks, Grand Forks Region Economic & Development Corp., and the Bank of North Dakota demonstrate a deep commitment toward supporting agriculture in the Grand Forks area. Grand Forks and the State of North Dakota set clear expectations for how projects like ours can be successful in a way that is environmentally and economically sound. This support makes Grand Forks perfect for agribusinesses like ours to grow and thrive.

Project Status

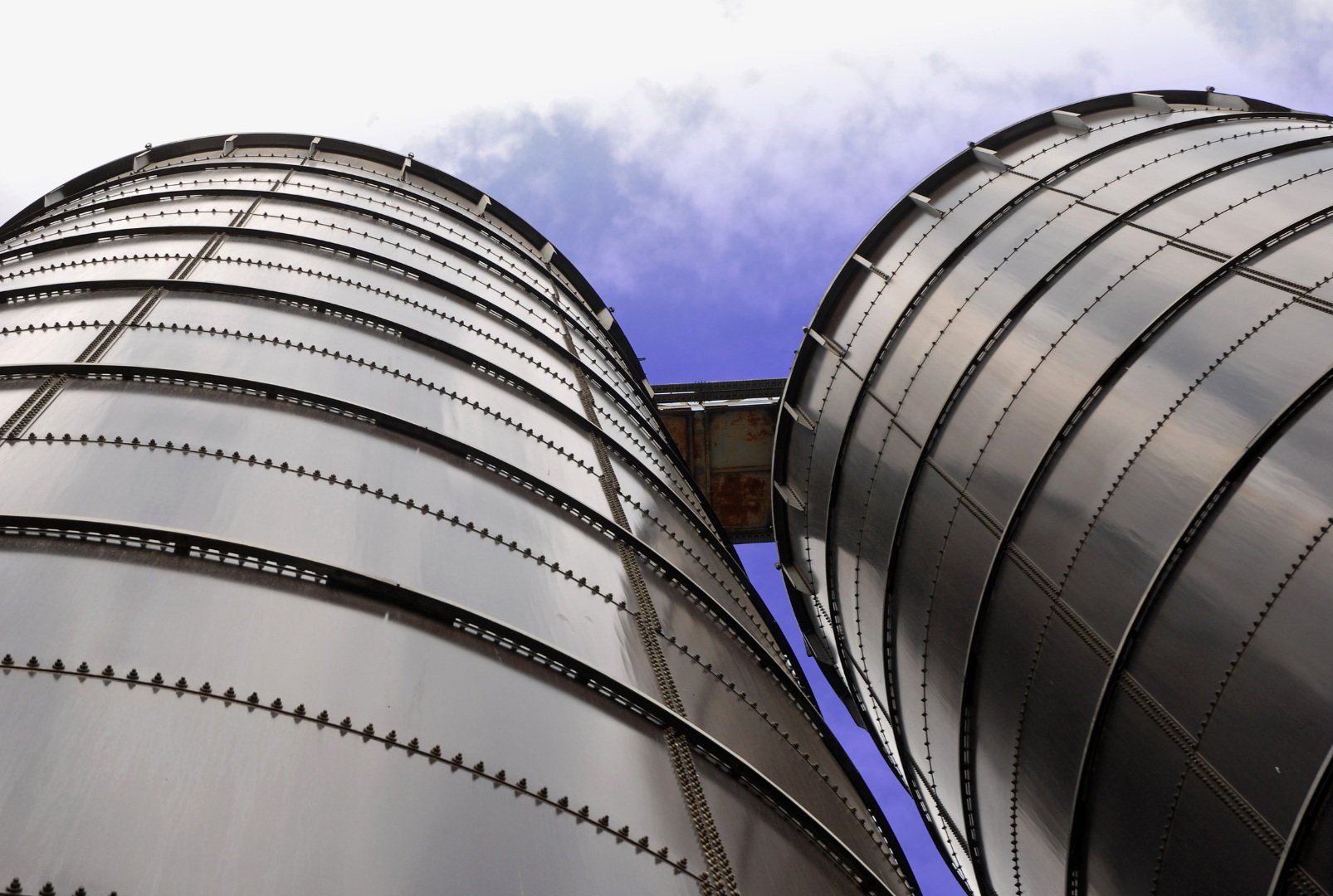

Epitome Energy has executed a letter of intent to build on a greenfield site just north of Grand Forks. The site features full access to rail, freeways, and all necessary utilities.

The facility will be designed and engineered by Fagen, Inc. – the #1 green energy developer in the U.S. The plant will be Fagen’s fifth soybean crush facility to date. Processing equipment for the facility will be designed and built by Crown Iron Works, a world leader in oilseed extraction technology.

Preliminary site map